Researchers at the University of Maryland have demonstrated a continuously operating optical fiber made of thin air.

The most common optical fibers are strands of glass that tightly confine light over long distances. However, these fibers are not well-suited for guiding extremely high-power laser beams due to glass damage and scattering of laser energy out of the fiber. Additionally, the need for a physical support structure means that glass fiber must be laid down long in advance of light signal transmission or collection.

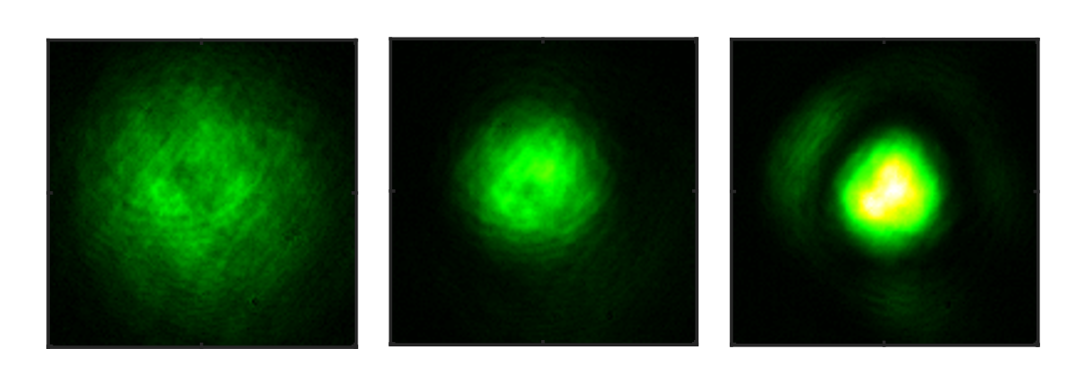

Professor Howard Milchberg and his group in the Depts. of Physics, ECE, and the Institute for Research in Electronics and Applied Physics at the University of Maryland have demonstrated an optical guiding method that beats both limitations, using auxiliary ultrashort laser pulses to sculpt fiber optic waveguides in the air itself. These short pulses form a ring of high-intensity light structures called “filaments”, which heat the air molecules to form an extended ring of low-density heated air surrounding a central undisturbed region; this is exactly the refractive index structure of an optical fiber. With air itself as the fiber, very high average powers can potentially be guided. And for collection of remote optical signals for detecting pollutants and radioactive sources, for example, the air waveguide can be arbitrarily “unspooled” and directed at the speed of light in any direction. An unguided continuous wave green laser beam (left), and the same beam guided by an air waveguide generated at 10 Hz (center) and at 1000 Hz (right). The air waveguide on the right is essentially continuously operating.

An unguided continuous wave green laser beam (left), and the same beam guided by an air waveguide generated at 10 Hz (center) and at 1000 Hz (right). The air waveguide on the right is essentially continuously operating.

In an experiment published in January in Physical Review X [Physical Review X 13, 011006 (2023)], graduate student Andrew Goffin and colleagues from Milchberg’s group showed that this technique can form 50-meter-long air waveguides that persist for tens of milliseconds until they dissipate from cooling by the surrounding air. Generated using only one watt of average laser power, these waveguides could theoretically guide megawatt average power laser beams, making them exceptional candidates for directed energy. The waveguide method is straightforwardly scalable to 1 kilometer and longer. However, the waveguide-generating laser in that work fired a pulse every 100 milliseconds (repetition rate of 10 Hz), with cooling dissipation over 30 milliseconds, leaving 70 milliseconds between shots with no air waveguide present. This is an impediment to guiding a continuous wave laser or collecting a continuous optical signal.

In a new Memorandum in Optica [Optica 10, 505 (2023)], Andrew Goffin, Andrew Tartaro, and Milchberg show that by increasing the repetition rate of the waveguide-generating pulse up to 1000 Hz (a pulse every millisecond), the air waveguide is continuously maintained by heating and deepening the waveguide faster than the surrounding air can cool it. The result is a continuously operating air waveguide that can guide an injected continuous wave laser beam. Because the waveguide is deepened by repetitive generation, guided light confinement efficiency improves by a factor of three at the highest repetition rate.

Continuous wave optical guiding significantly improves the utility of air waveguides: it increases the maximum average laser power one can transport and maintains the guiding structure for use in continuous collection of remote optical signals. And because kilometer-scale and longer waveguides are wider, cooling is slower and a repetition rate well below 1 kHz will be needed to maintain the guide. This more lenient requirement makes continuous air waveguiding over kilometer and longer ranges easily achievable with existing laser technology and modest power levels.

“With an appropriate laser system for generating the waveguide, long-distance continuous guiding should be easily doable”, says Goffin, “Once we have that, it’s just a matter of time before we’re transmitting high power continuous laser beams and detecting pollutants from miles away.”